UMS Gas Radial Engine Enthusiasts Rabbit Hole

#276

My Feedback: (1)

So , shortly after my last post the 7-50 started having some problems. On the early runs it could idle comfortably at 1500rpm and 6300rpm at the top with a Turnigy 18x10. I switched to a 20x10 MA classic to keep the revs down and it was still performing great. Then all of the sudden it wasn't  . I switched back to the 18x10 and could barely pull 5400rpm and solid idle went up to 2000rpm. I rechecked valve clearance mixed up a fresh batch of 32-1 fuel and nothing changed. I also cleaned the plugs again and also gapped them , still the same. I decided to remove the exhaust ring to see if that helped and by doing that I was able to feel individual cylinder action.

. I switched back to the 18x10 and could barely pull 5400rpm and solid idle went up to 2000rpm. I rechecked valve clearance mixed up a fresh batch of 32-1 fuel and nothing changed. I also cleaned the plugs again and also gapped them , still the same. I decided to remove the exhaust ring to see if that helped and by doing that I was able to feel individual cylinder action.

All cylinders were firing when rpms were below 3000 but only 3 cylinders were firing properly above that. Cylinders 1,3,5, & 6 weren't firing right. I swapped 1 and 2 plugs and it seemed a little better. Well today I changed out 4 plugs with new ones and problem solved!! Back up to 6300rpm on the 18x10.

These were/are Rcexl stock plugs as the new plugs came in conversion kits from CH Ignitions. Has anyone else had problems with these? Are the more expensive ($20 each) Rcexl iridium plugs better? I also thought I might regulate the ignition voltage up to 9v (9.6v is the limit) from 7.2v to see if it runs more consistently as towards the end of the run one of the new plugs seemed to be falling out too.

. I switched back to the 18x10 and could barely pull 5400rpm and solid idle went up to 2000rpm. I rechecked valve clearance mixed up a fresh batch of 32-1 fuel and nothing changed. I also cleaned the plugs again and also gapped them , still the same. I decided to remove the exhaust ring to see if that helped and by doing that I was able to feel individual cylinder action.

. I switched back to the 18x10 and could barely pull 5400rpm and solid idle went up to 2000rpm. I rechecked valve clearance mixed up a fresh batch of 32-1 fuel and nothing changed. I also cleaned the plugs again and also gapped them , still the same. I decided to remove the exhaust ring to see if that helped and by doing that I was able to feel individual cylinder action.All cylinders were firing when rpms were below 3000 but only 3 cylinders were firing properly above that. Cylinders 1,3,5, & 6 weren't firing right. I swapped 1 and 2 plugs and it seemed a little better. Well today I changed out 4 plugs with new ones and problem solved!! Back up to 6300rpm on the 18x10.

These were/are Rcexl stock plugs as the new plugs came in conversion kits from CH Ignitions. Has anyone else had problems with these? Are the more expensive ($20 each) Rcexl iridium plugs better? I also thought I might regulate the ignition voltage up to 9v (9.6v is the limit) from 7.2v to see if it runs more consistently as towards the end of the run one of the new plugs seemed to be falling out too.

The following users liked this post:

Robert Dochterman (04-11-2024)

#277

Member

Just 2 comments:

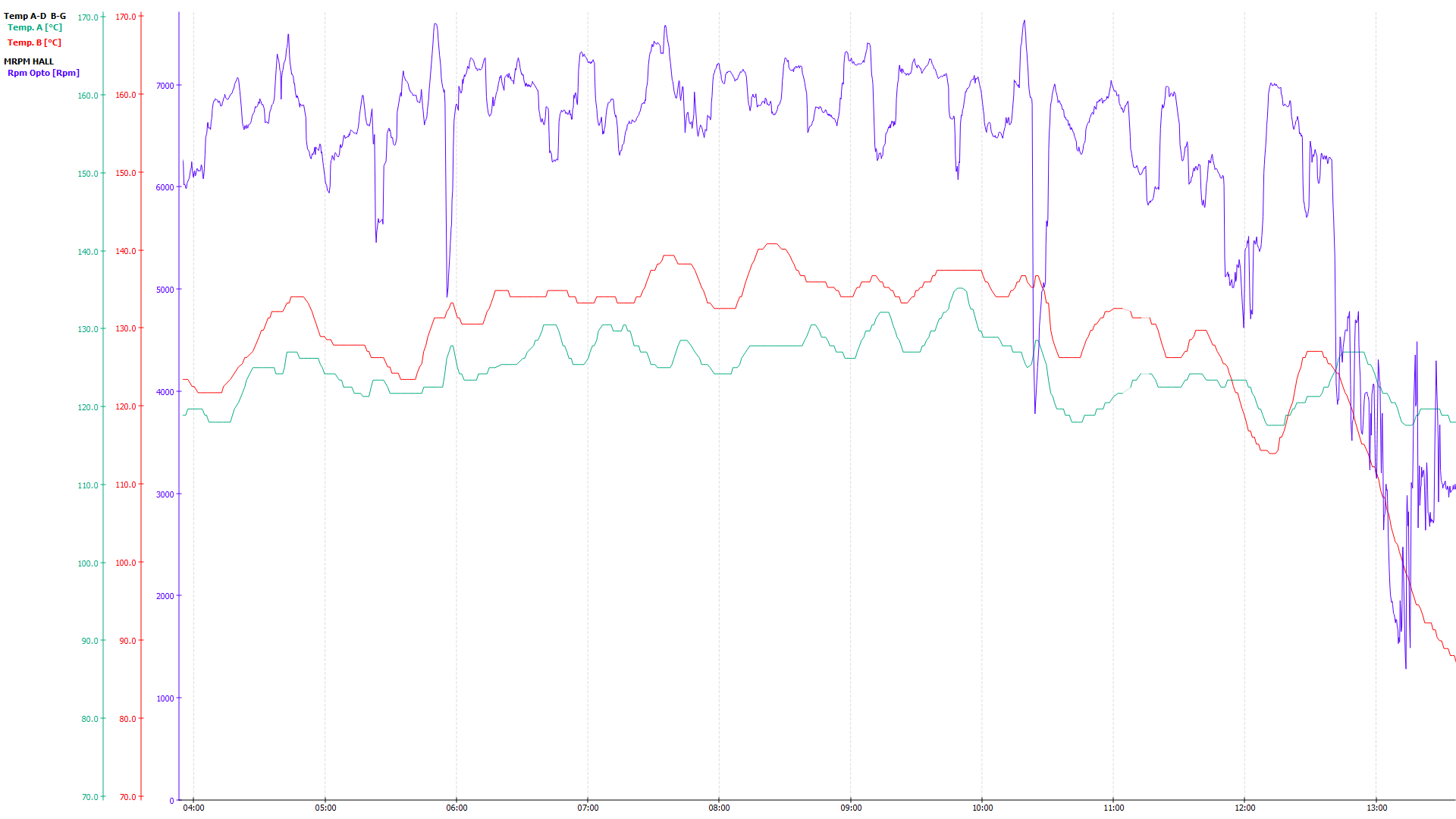

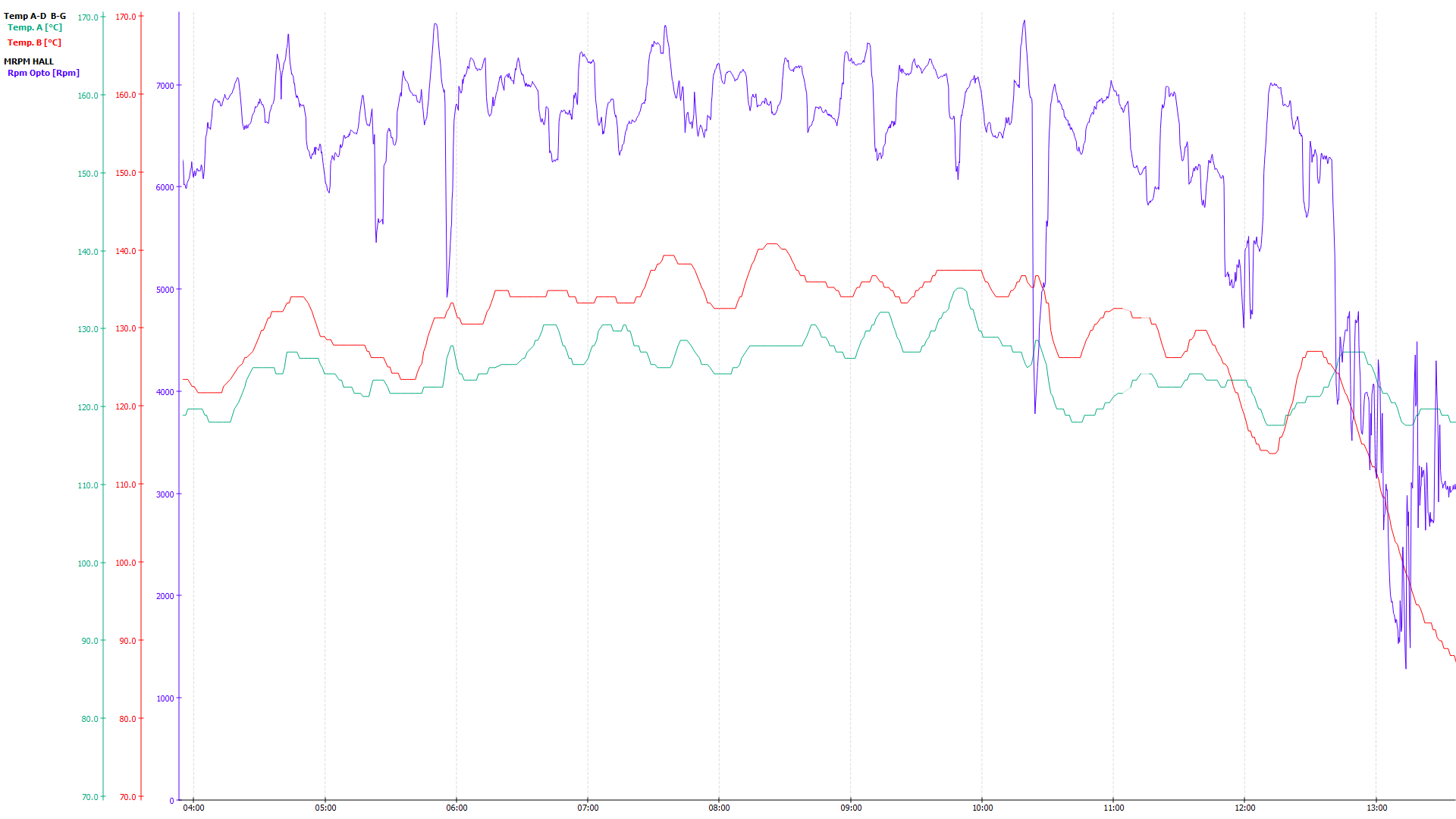

On the one hand, it is difficult to measure temperature on an aluminum surface with a laser gun. The only way to get an exact value is to stick the sensor to the surface.

And on the other hand, there are enormous differences between the different surfaces of the same engine. And on the same engine we can measure 100°C (210°F) at the bottom of the cylinder as well as 150°C (300°F) under the fin at the exhaust outlet (in general the hottest point of the engine)

Without any operating problems.

Exemple T°C measured on a Saito FG61TS with sensors glued to the fins.

JM

On the one hand, it is difficult to measure temperature on an aluminum surface with a laser gun. The only way to get an exact value is to stick the sensor to the surface.

And on the other hand, there are enormous differences between the different surfaces of the same engine. And on the same engine we can measure 100°C (210°F) at the bottom of the cylinder as well as 150°C (300°F) under the fin at the exhaust outlet (in general the hottest point of the engine)

Without any operating problems.

Exemple T°C measured on a Saito FG61TS with sensors glued to the fins.

JM

The following users liked this post:

Robert Dochterman (04-11-2024)

#278

Hi all. The site has been making my phone sick lately. Seems better now lol. Got three flights on my 125 yesterday. Been flying it uncowled recently due to sticking valves found on pre flight inspections. . Six flights without a reoccurrence, all after juicing the external valve stems with seafoam and then 1 ounce admixture with the Amsoil Dominator. Your suggestion seems to be working Tom. I regularly added S.F. to my fuels in the past. Just sorta forgot about it in recent years. If anyone else is experiencing this inconvenience, I'd heartily recommend giving it a try. I think the valve stem to guide fitment is a little tight on these engines. There is a second one at our field experiencing the same quirk.

I'm with you on heat J. Heat gun testing is very subjective with dissimilar metals..I have standardized my procedure to test at the metallic exhaust nut in the heads. asy to "hit" in a consistent manner while cowled or open. If I'm not seeing anything above 240 I am happy. I am used to between 220 -240 if they are all firing. Below 125-150 if not. (Rare for my engine) 300 would have me shutting down and investigating for a cause.

I have never seen anything above 260 on my engine and that was during break in on the bench during short run heat cycling with the recommended prop. . I fan cooled it during those initial runs.

I run a Ramsover VarioPROP now pitched to give me 5100 wot. As with Tom, I am looking for scale sound and performance, with longevity a top priority. I rarely fly anywhere near wot, and never run hard down lines. I have never "lost" a pushrod from overreving or excessive heat expanding the valve stems.

Nice to be back with you Radial Enthusiasts.Hope your flying sessions are going well as the days get longer.

Aaron-

I'm with you on heat J. Heat gun testing is very subjective with dissimilar metals..I have standardized my procedure to test at the metallic exhaust nut in the heads. asy to "hit" in a consistent manner while cowled or open. If I'm not seeing anything above 240 I am happy. I am used to between 220 -240 if they are all firing. Below 125-150 if not. (Rare for my engine) 300 would have me shutting down and investigating for a cause.

I have never seen anything above 260 on my engine and that was during break in on the bench during short run heat cycling with the recommended prop. . I fan cooled it during those initial runs.

I run a Ramsover VarioPROP now pitched to give me 5100 wot. As with Tom, I am looking for scale sound and performance, with longevity a top priority. I rarely fly anywhere near wot, and never run hard down lines. I have never "lost" a pushrod from overreving or excessive heat expanding the valve stems.

Nice to be back with you Radial Enthusiasts.Hope your flying sessions are going well as the days get longer.

Aaron-

The following users liked this post:

Robert Dochterman (04-11-2024)

#279

My Feedback: (47)

Hello Guys,

I am going to be installing my UMS 150 into a Mamba 120 and its going to be a great fit. I want to run a three-blade propeller and just looking to see what is working for you guys that are running them. I like Biela Prop and Aircraft International list a 26 x 16 x 3 for the Moki 150 and I would assume that it would be close for the UMS as well. I have been searching and not coming up with a lot of definitive information or comments on UMS 150 three blade combos. I did a search of the forums as well and I do apologize if I missed it and this has already been covered. Thanks,.

Jason

I am going to be installing my UMS 150 into a Mamba 120 and its going to be a great fit. I want to run a three-blade propeller and just looking to see what is working for you guys that are running them. I like Biela Prop and Aircraft International list a 26 x 16 x 3 for the Moki 150 and I would assume that it would be close for the UMS as well. I have been searching and not coming up with a lot of definitive information or comments on UMS 150 three blade combos. I did a search of the forums as well and I do apologize if I missed it and this has already been covered. Thanks,.

Jason

Last edited by JRSmith; 04-12-2024 at 08:25 AM.

#280

Hi Jason.. My name is Aaron. AKA Hyjinx on this thread I started a few years ago. While I can't answer this question I am happy you posed it here. It is my sincere hope you have a satisfactory experience with your UMS Radial. Please continue to share your findings on this format as that will benefit all. Sincerely. Aaron-

The following users liked this post:

Robert Dochterman (04-12-2024)

#282

My Feedback: (47)

Hi Jason.. My name is Aaron. AKA Hyjinx on this thread I started a few years ago. While I can't answer this question I am happy you posed it here. It is my sincere hope you have a satisfactory experience with your UMS Radial. Please continue to share your findings on this format as that will benefit all. Sincerely. Aaron-

Thanks, I will share my findings and thoughts as I go. Adrian recommended whatever prop Aircraft International recommends for the Moki 150 and it looks like a 26 x 16 x 3 and a 25 x 16 x 3 are what's listed on the site. I am not sure which one I am going to go with, hoping to get some feedback from actual user experiences, but if not I will more then likely buy the 26 x 16 x 3 to start. But I don't want to keep buying props as that can get expensive fairly fast,

This is my first UMS 150, I have had a couple Moki 250's and 150's over the years. But still have tons to learn, so thanks for getting the thread going.

Here is the schematic from my APS fuel pump I will be using with the UMS 150.

Last edited by JRSmith; 04-12-2024 at 02:19 PM.

#283

My Feedback: (1)

I got some more runs in today totaling more than 1-1/2 gallons through it so far. It seems either the plugs are a problem or the plugs during break-in are fowling out. Either way it is definitely a plug issue. It ran exceptionally today prompting me to re-install the 20x10 and it is now producing just under 13lbs of thrust at 5800ish rpms with a reliable idle of around 1000rpms. It is very close to me trusting it in my Hanger 9 30cc ultra stick.

Chris

Chris

#284

Thank you Jason..When I bought my Moki 250-7 from Vogelsang Aeroscale Gotz was emphatic about a specific propeller. I felt comfortable with his recommendation, so I followed his suggestion. Other radials I own I have also followed the manufacturers recommendations in operations manuals. Ongoing after recommended break ins I have used the VarioPROP brand for infinite pitch adjustment as well as scale appearance of the hub and blade styles. After the initial investment in the hub, the blade sets are cost effective and durable, well balanced and the principal owner/designed is good to work with. Communication and shipping are also good even with the language translations. I really appreciate the ability to tailor my desired running criteria with RPM and heat generation/ flight characteristics etc without having to experiment with individual fixed pitch offerings. I would suggest you consider this system for your three blades application respectfully.

Thank you so much for the plumbing confirmation. Probably a strange request from a long term user of these devices such as myself lol.

I did a short set of tutorials on the VarioPROP for a friend on u tube if you would like a quick overview. He found initial assembly a bit confusing, as I did as well. Google any keyword and it should be easy to locate on u tube. I appreciate your helpful response. Welcome to this forum. There is a wealth of good helpful insight here from users or these wonderful scale marvels. Your ongoing input is greatly appreciated.

Aaron-

Thank you so much for the plumbing confirmation. Probably a strange request from a long term user of these devices such as myself lol.

I did a short set of tutorials on the VarioPROP for a friend on u tube if you would like a quick overview. He found initial assembly a bit confusing, as I did as well. Google any keyword and it should be easy to locate on u tube. I appreciate your helpful response. Welcome to this forum. There is a wealth of good helpful insight here from users or these wonderful scale marvels. Your ongoing input is greatly appreciated.

Aaron-

#285

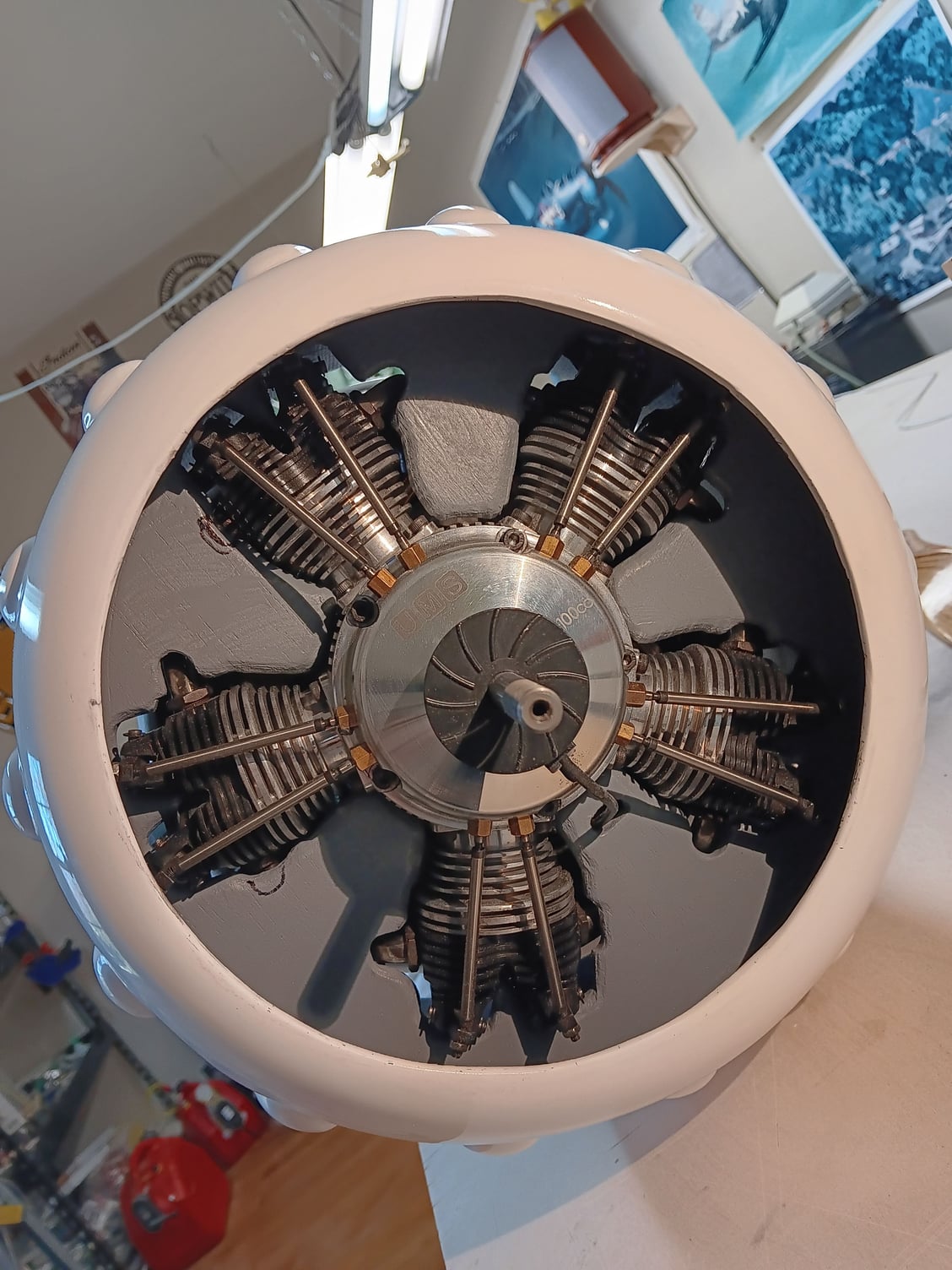

I'm a long-time modeler but new to radials, and I wanted to share what I've learned. I have a UMS 5-100, and it is of excellent quality, runs well, and sounds awesome. Support from Adrian at CH ignition is great.First, as others have mentioned, check the ignition sensor screws. Mine were very loose, but I only lightly tightened them and secured with a small dab of glue externally on the screw heads. And I made sure there was clearance between the sensor and hub.The valve clearance was a little loose new, but i left it as is for the first two tanks of fuel.For the first tank of fuel, I was able to start it with a 12 volt geared starter on a prop hub. With more breakin, the compression increased, and i had to use a Sullivan 24 volt starter with a 4-1 gear reduction. The increase starter torque would loosen the prop hub, so i had to use a 3" bolt on aluminum spinner. The Sullivan contacts were welding under the heavier amp draw, so I added a 120 amp relay, which works perfectly.After two tanks of fuel, it was time to adjust the valves. The instructions say to use a wood dowel to find TDC. That worked well until it didn't. The wood dowel cracked leaving a piece inside the cylinder. The only way to get it out was to remove the head screws, loosen the intake and exhaust pipes enough to raise the cylinder head 1/8" and I was able to remove the wood dowel piece. When reassembling, be very careful not to cross thread the pipe. A better method for for finding TDC is just to watch the valves then look in the spark plug hole to see the piston at TDC. I use a wood block to turn the engine over. Once i find TDC i align another hole in the wood block to the center of the cylinder. This will track for TDC on each cylinder. I've finished the breakin per instructions staying under 4000 rpms. My temps were running at 225 degrees. As I'm ready to go for full rpm of 5500 the temps started to rise. Next before I run at extended full rpm I'll need to tune the needle valves more and I will be using a cowling on the test stand. I'm trying to design some cylinder baffling, not easy to do. I want something that is not just a blocking of the airspace between cylinders, but something that comes to a point in-between the cylinders to funnel

and deflect the maximum amount of air around the cylinders. Picture a baffle is just a test. Would be nice to have something 3D printed.

and deflect the maximum amount of air around the cylinders. Picture a baffle is just a test. Would be nice to have something 3D printed.

#286

I'm a long-time modeler but new to radials, and I wanted to share what I've learned. I have a UMS 5-100, and it is of excellent quality, runs well, and sounds awesome. Support from Adrian at CH ignition is great.First, as others have mentioned, check the ignition sensor screws. Mine were very loose, but I only lightly tightened them and secured with a small dab of glue externally on the screw heads. And I made sure there was clearance between the sensor and hub.The valve clearance was a little loose new, but i left it as is for the first two tanks of fuel.For the first tank of fuel, I was able to start it with a 12 volt geared starter on a prop hub. With more breakin, the compression increased, and i had to use a Sullivan 24 volt starter with a 4-1 gear reduction. The increase starter torque would loosen the prop hub, so i had to use a 3" bolt on aluminum spinner. The Sullivan contacts were welding under the heavier amp draw, so I added a 120 amp relay, which works perfectly.After two tanks of fuel, it was time to adjust the valves. The instructions say to use a wood dowel to find TDC. That worked well until it didn't. The wood dowel cracked leaving a piece inside the cylinder. The only way to get it out was to remove the head screws, loosen the intake and exhaust pipes enough to raise the cylinder head 1/8" and I was able to remove the wood dowel piece. When reassembling, be very careful not to cross thread the pipe. A better method for for finding TDC is just to watch the valves then look in the spark plug hole to see the piston at TDC. I use a wood block to turn the engine over. Once i find TDC i align another hole in the wood block to the center of the cylinder. This will track for TDC on each cylinder. I've finished the breakin per instructions staying under 4000 rpms. My temps were running at 225 degrees. As I'm ready to go for full rpm of 5500 the temps started to rise. Next before I run at extended full rpm I'll need to tune the needle valves more and I will be using a cowling on the test stand. I'm trying to design some cylinder baffling, not easy to do. I want something that is not just a blocking of the airspace between cylinders, but something that comes to a point in-between the cylinders to funnel

and deflect the maximum amount of air around the cylinders. Picture a baffle is just a test. Would be nice to have something 3D printed.

and deflect the maximum amount of air around the cylinders. Picture a baffle is just a test. Would be nice to have something 3D printed.

#287

My Feedback: (62)

Here is my baffle for the Waco and 5-100. It is balsa plywood consisting of three 3/32 sheets at 120 degrees to each other. A point source light from the celling shining on paper with the engine sitting on it is traced around the shadow. Then after cutting out the boarders are tapered in. A great deal of work.

#289

My Feedback: (62)

Robert, There is an issue with carburation on the 5-100. When you tune the engine for "ideal" running at idle and full throttle there will exist a lean condition around 1500 to 2500 rpm. The engine when slowly throttled up or kept at this range of rpm the engine will lean out soon and quit! To fix this adjust the low needle to a richer setting and readjust the throttle idle stop or your throttle trim up to reestablish a good reliable low idle. So many people like to "vroom vroom" the engine thinking it is adjusted correctly. Doing this will "hide" the lean condition zone. Radials actually don't like very rapid throttle changes. I adjust my throttle servo speeds to 1.5 seconds to full throttle and one second back down to idle. -Tom

#291

Robert, There is an issue with carburation on the 5-100. When you tune the engine for "ideal" running at idle and full throttle there will exist a lean condition around 1500 to 2500 rpm. The engine when slowly throttled up or kept at this range of rpm the engine will lean out soon and quit! To fix this adjust the low needle to a richer setting and readjust the throttle idle stop or your throttle trim up to reestablish a good reliable low idle. So many people like to "vroom vroom" the engine thinking it is adjusted correctly. Doing this will "hide" the lean condition zone. Radials actually don't like very rapid throttle changes. I adjust my throttle servo speeds to 1.5 seconds to full throttle and one second back down to idle. -Tom

The following users liked this post:

Hyjinx (04-15-2024)

#293

My Feedback: (47)

Thank you Jason..When I bought my Moki 250-7 from Vogelsang Aeroscale Gotz was emphatic about a specific propeller. I felt comfortable with his recommendation, so I followed his suggestion. Other radials I own I have also followed the manufacturers recommendations in operations manuals. Ongoing after recommended break ins I have used the VarioPROP brand for infinite pitch adjustment as well as scale appearance of the hub and blade styles. After the initial investment in the hub, the blade sets are cost effective and durable, well balanced and the principal owner/designed is good to work with. Communication and shipping are also good even with the language translations. I really appreciate the ability to tailor my desired running criteria with RPM and heat generation/ flight characteristics etc without having to experiment with individual fixed pitch offerings. I would suggest you consider this system for your three blades application respectfully.

Thank you so much for the plumbing confirmation. Probably a strange request from a long term user of these devices such as myself lol.

I did a short set of tutorials on the VarioPROP for a friend on u tube if you would like a quick overview. He found initial assembly a bit confusing, as I did as well. Google any keyword and it should be easy to locate on u tube. I appreciate your helpful response. Welcome to this forum. There is a wealth of good helpful insight here from users or these wonderful scale marvels. Your ongoing input is greatly appreciated.

Aaron-

Thank you so much for the plumbing confirmation. Probably a strange request from a long term user of these devices such as myself lol.

I did a short set of tutorials on the VarioPROP for a friend on u tube if you would like a quick overview. He found initial assembly a bit confusing, as I did as well. Google any keyword and it should be easy to locate on u tube. I appreciate your helpful response. Welcome to this forum. There is a wealth of good helpful insight here from users or these wonderful scale marvels. Your ongoing input is greatly appreciated.

Aaron-

I an a huge fan of Christian at VarioProp and have had four setups over the years. I currently have this for my T-28, but I think this might look really cool on the Flex Mamba 120, but its only 24" diameter and the Mamba has a big cowl, but the T-28 cowl is just as big! But like you said, you can adjust the pitch as needed and best performance. But it does add a fair amount of weight up front, which will need to be adjusted for with component placement. My T-28 is a long way off, just sitting on the shelve for now, so I might divert this prop! I am working on the test stand now and will hopefully have this setup to run within the next couple of week, but we have a fairly busy couple of weeks with baseball. Talk soon,

Jason

The following users liked this post:

Hyjinx (04-15-2024)

#294

Aaron-

#295

Hello Aaron,

I an a huge fan of Christian at VarioProp and have had four setups over the years. I currently have this for my T-28, but I think this might look really cool on the Flex Mamba 120, but its only 24" diameter and the Mamba has a big cowl, but the T-28 cowl is just as big! But like you said, you can adjust the pitch as needed and best performance. But it does add a fair amount of weight up front, which will need to be adjusted for with component placement. My T-28 is a long way off, just sitting on the shelve for now, so I might divert this prop! I am working on the test stand now and will hopefully have this setup to run within the next couple of week, but we have a fairly busy couple of weeks with baseball. Talk soon,

Jason

I an a huge fan of Christian at VarioProp and have had four setups over the years. I currently have this for my T-28, but I think this might look really cool on the Flex Mamba 120, but its only 24" diameter and the Mamba has a big cowl, but the T-28 cowl is just as big! But like you said, you can adjust the pitch as needed and best performance. But it does add a fair amount of weight up front, which will need to be adjusted for with component placement. My T-28 is a long way off, just sitting on the shelve for now, so I might divert this prop! I am working on the test stand now and will hopefully have this setup to run within the next couple of week, but we have a fairly busy couple of weeks with baseball. Talk soon,

Jason

#296

Hello Guys,

I am going to be installing my UMS 150 into a Mamba 120 and its going to be a great fit. I want to run a three-blade propeller and just looking to see what is working for you guys that are running them. I like Biela Prop and Aircraft International list a 26 x 16 x 3 for the Moki 150 and I would assume that it would be close for the UMS as well. I have been searching and not coming up with a lot of definitive information or comments on UMS 150 three blade combos. I did a search of the forums as well and I do apologize if I missed it and this has already been covered. Thanks,.

Jason

I am going to be installing my UMS 150 into a Mamba 120 and its going to be a great fit. I want to run a three-blade propeller and just looking to see what is working for you guys that are running them. I like Biela Prop and Aircraft International list a 26 x 16 x 3 for the Moki 150 and I would assume that it would be close for the UMS as well. I have been searching and not coming up with a lot of definitive information or comments on UMS 150 three blade combos. I did a search of the forums as well and I do apologize if I missed it and this has already been covered. Thanks,.

Jason

Want to get a suitable 2 blade for bench running / break in.

#297

My Feedback: (47)

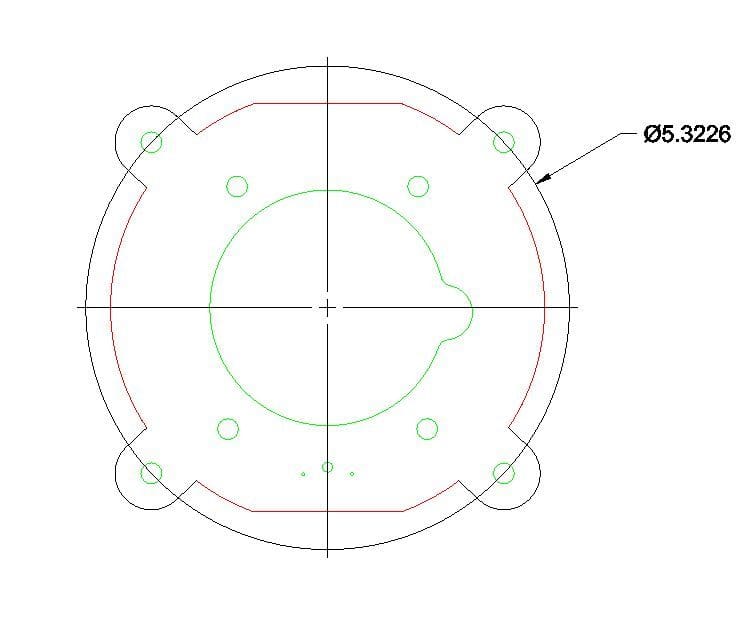

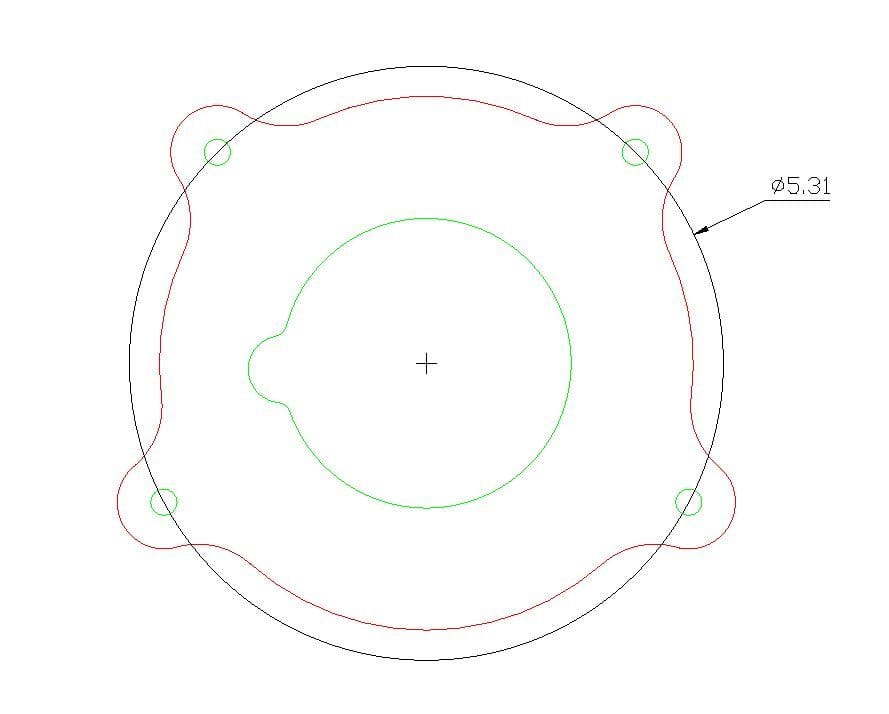

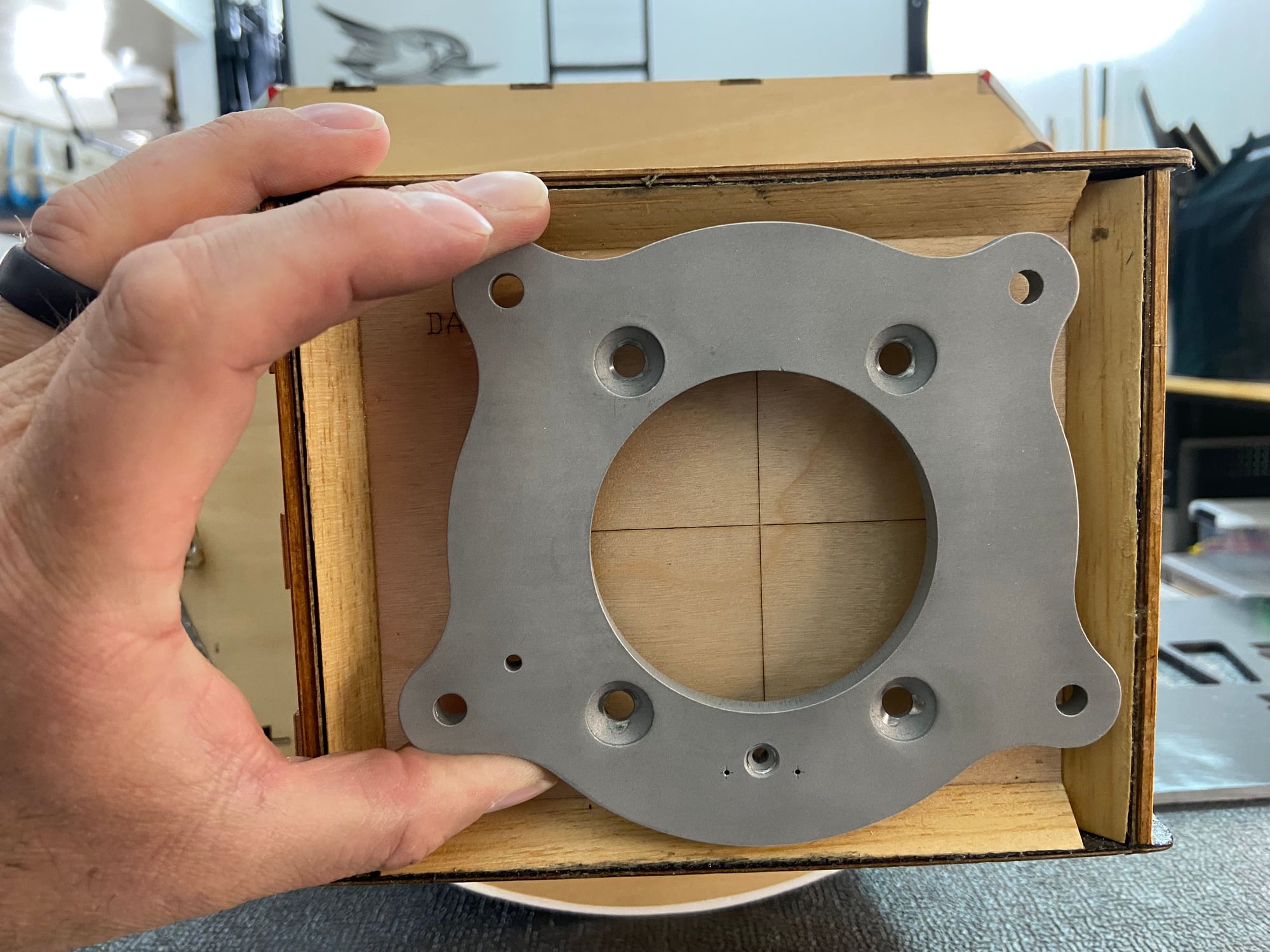

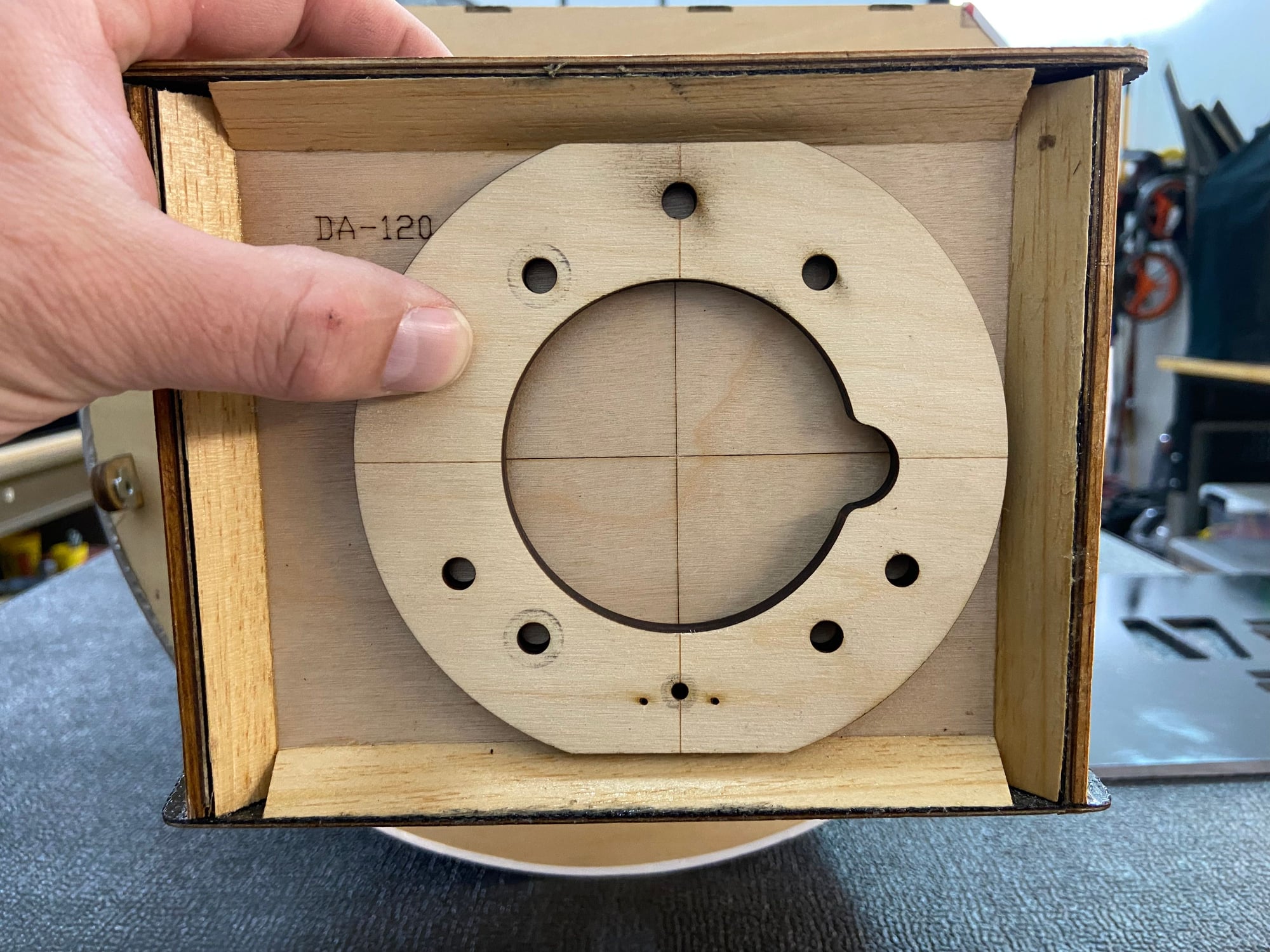

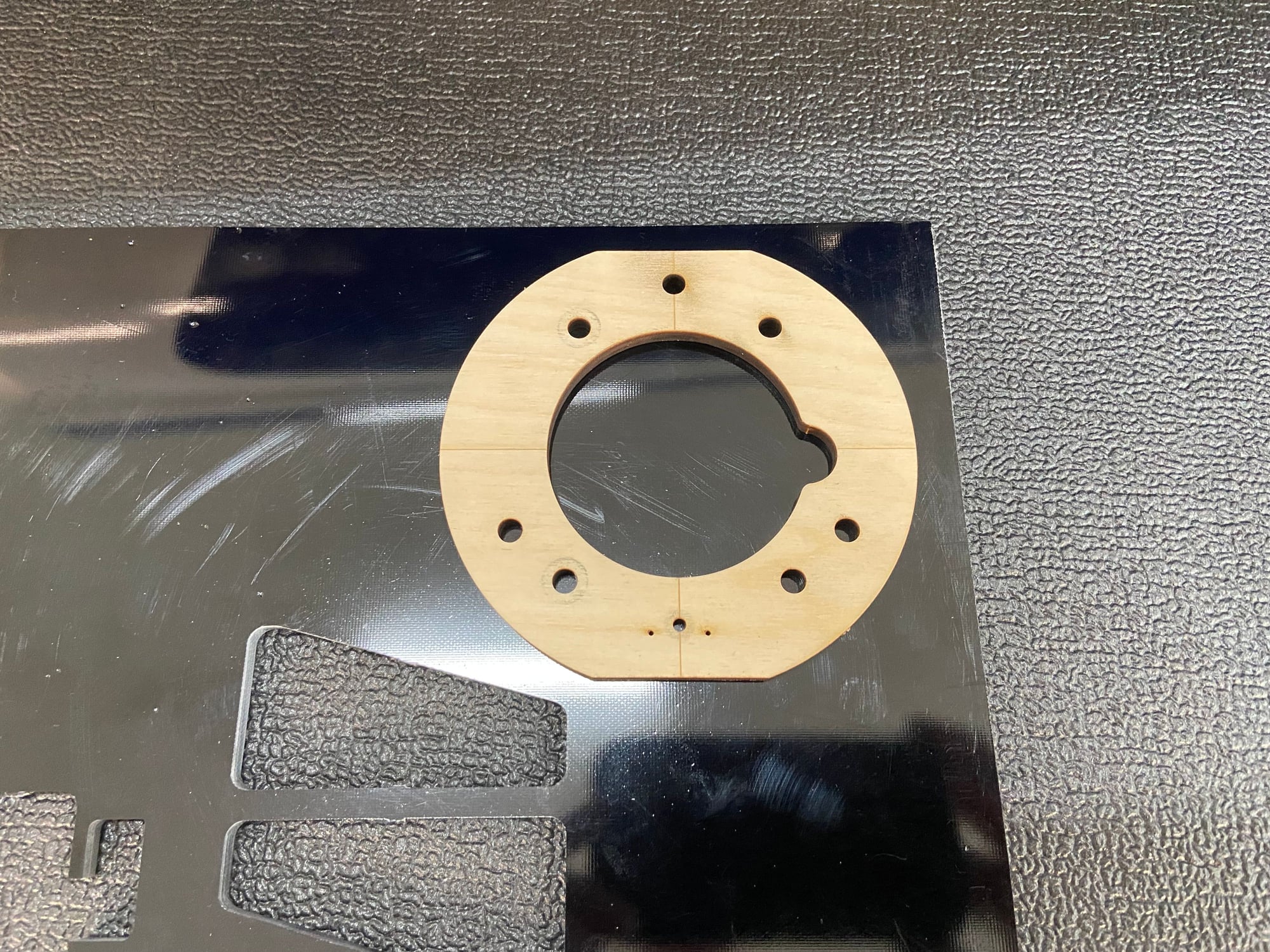

Thought I would share this with the group. I have been thinking about mounting the motor and the backplate supplied with the UMS 150 is rather large and is a little too big for the Mamba firewall. My Moki 250s were half the size of this UMS one! So after thinking about it for a little bit, why not make another backplate and instead of the four countersink screws, why not pass those bolts through the firewall too. This is what I came up with. And, NO I am not using wood. that was only for test fit. I plan on using 1/4" Flame-Retardant Garolite G-10/FR4 Sheet, I could mill it out of aluminum, but with the bolts passing through, I did not see the need, and I have the 1/4" G10 on hand. Plenty strong and is just being used to spread the load.

The three additional 6mm holes at approximately 120 degree spacing are to attach the plate(s) to the firewall and it will help with installing the motor. I hope this makes sense and let me know if I am missing anything. The G10 I am using is rated to 280F, so not too worried about motor temps. And if that area gets that hot, I have a fire.

Talk soon.

#298

Christian is excellent to work with, I have 2 of his Vario props, one on my FW-190 a 3 blade set up and now the 3 blade similar to Jason for my T-28, that is a 28" diameter.

Last edited by planenutzz; 04-15-2024 at 01:47 PM.

The following users liked this post:

Hyjinx (04-15-2024)

The following users liked this post:

Hyjinx (04-15-2024)

#300

My Feedback: (47)

Update on the previous post on the motor plate and a little discussion with Peter, I have relocated the outer mounting holes back to the same diameter as the stock UMS150 mount. I am still undecided if I am going to run it, I need to do a sanity check with a couple of engineering friends. I think it will work, but I may be missing something. I know the G10 is stronger is almost every category as compared to the aluminum, but again, I may be missing something. For reference, my Moki 250 has a bolt circle of 3.54" with three bolts, the Valach 250 is 4.48" with four bolts and the UMS 150 is 5.31" with four bolts. The mount in the current design as pictured is 5.32". I added radius to all the corners on the tabs as shown in the actual pictures.

Talk soon guys.